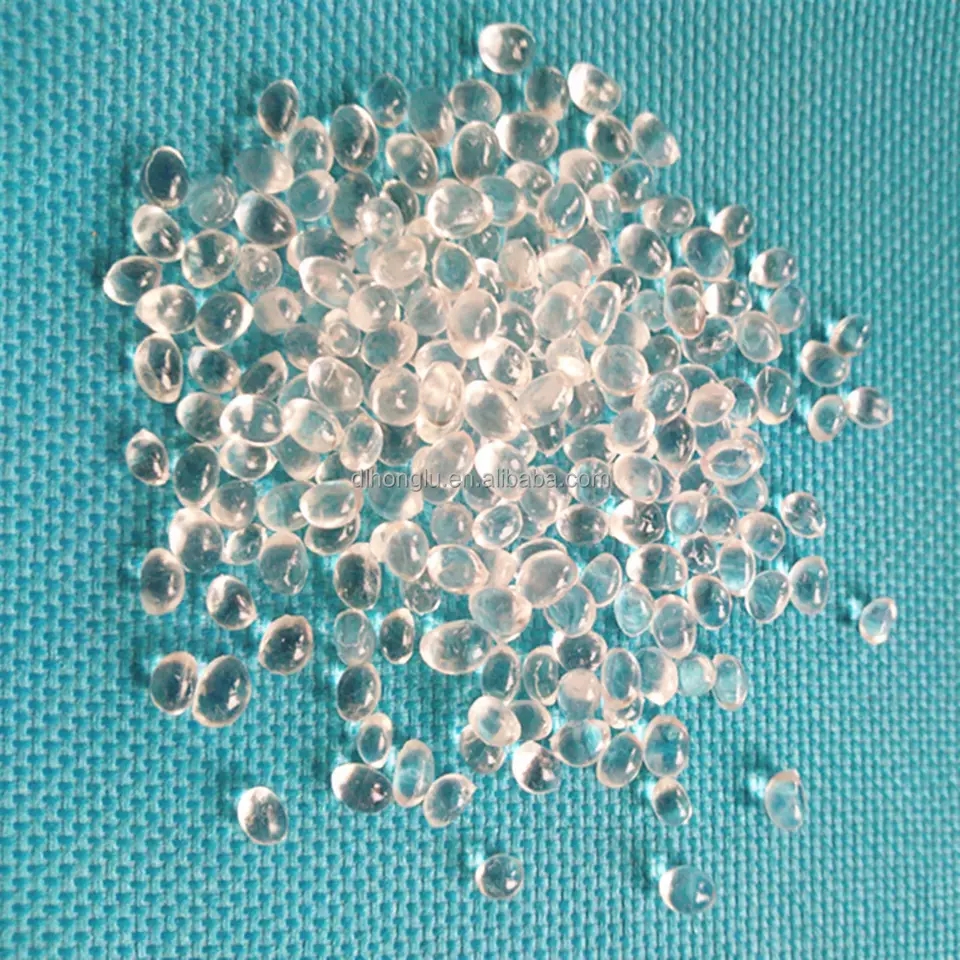

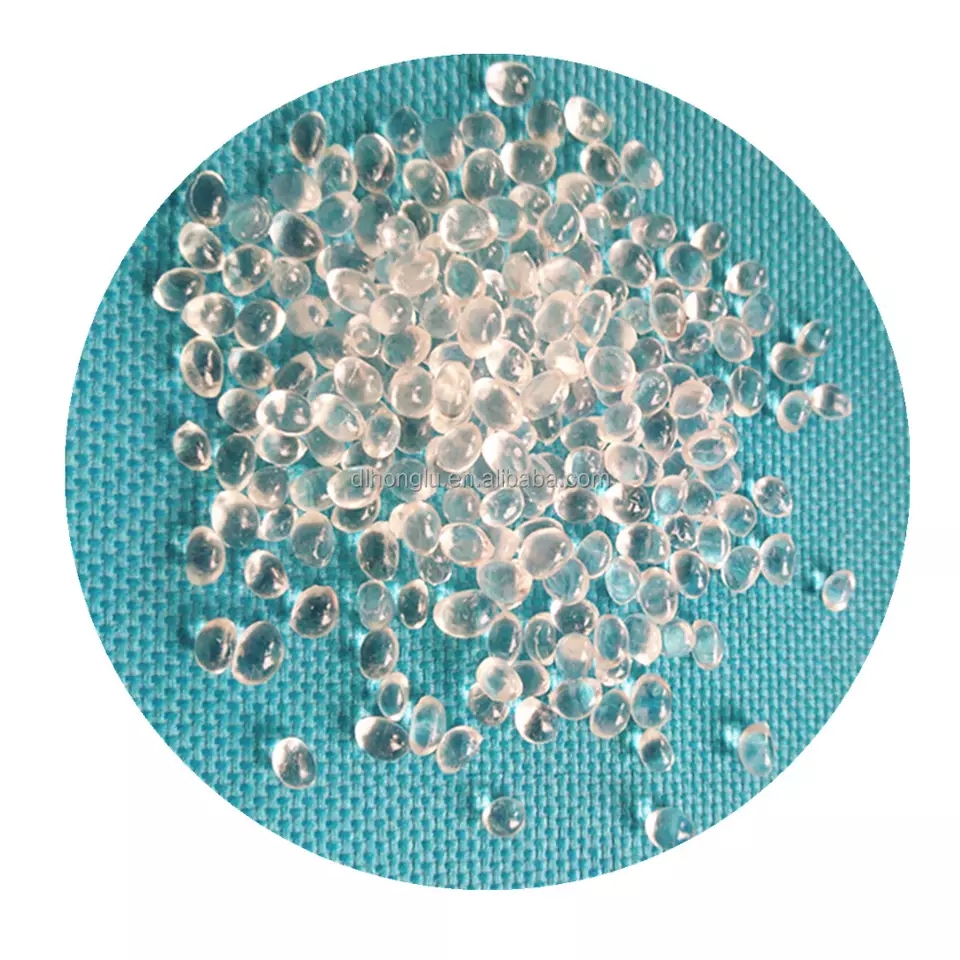

Product Introduction:

Eva material, chemical name is ethylene vinyl acetate copolymer, which is an extremely common material. It is a kind of midsole material that is common in daily life. Finished products made of Eva material have good softness, shock resistance, anti-skid, and pressure resistance, such as our common EVA slippers, cotton shoes, EVA mobile phone protective covers, EVA conduits, etc

Eva plastic Granule for Hot melt adhesives:

| Product Name | Ethylene-Vinyl Acetate Resin (EVA) |

| Appearance | White and Transparent Granules |

| HS code | 3901300000 |

| Place of Origin | HeBei ,China |

| Component Content of Black or Color Granules | 0 |

| Proportion of Ethylene | 72% |

| Proportion of Vinyl Acetate (VA) | 28% |

| Backing Material | Ethylene vinyl acetate resin (EVA)100% |

| MFR(g/10min) | 150 |

| Density | 0.945g/cm |

| Application | Hot melt adhesives |

EVA Granules For Shoes making:

| EVA 18J3 | ||

| ITEM | Specifications | RESULTS OF ANALYSIS |

| Black grain,PCS/KG | 0 | 0 |

| Color grain,PCS/KG | ≤10 | 0 |

| Big and small grain ,PCS/KG | ≤10 | 0 |

| Trailing grain,PCS/KG | ≤20 | 2 |

| Floccule,g/kg | ≤0.02 | 0 |

| VA,%(wt) | 18(+/-)1 | 17.3 |

| Melt mass flow rate,g/10min | 2.8(+/-)0.5 | 3.17 |

| Density,(23 ℃)g/m3 | As report | 0.937 |

| Melting peak temperature,℃ | As report | 90 |

EVA plastic granules for electric wire and cable:

| item | value |

| Product name | injection molding black masterbatch |

| Carrier | PP/PE(Can be customized) |

| Moisture(<%) | 0.1 |

| Compatibility | PE/PP/LLDPE/HDPE/LDPE/ABS/PS/PA/PVC/EVA |

| MFI/MFR(190℃/21.6KG) | 12-29g/10min |

| Appearance | 2.5*3.0mm black taper granule |

| Temperature resistance | 120℃-300℃ |

| Recommended Diagnose | 1%–3% |

| Carbon Black Content | 10%–50% |

| Eco Friendly | ROHS(SGS) |

| Dispersion | High |

| Gloss grades | High gloss |

| Mobility Resistance | Grade 4 |

| Volatility(<%) | 0.1 |

| Package | 25kg/bag |